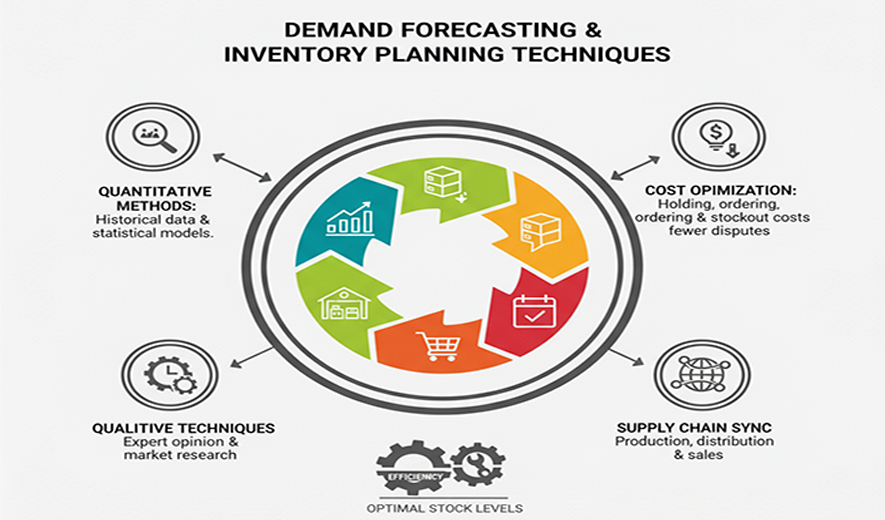

Demand Forecasting & Inventory Planning Techniques

Demand forecasting is the process of predicting future customer demand for products and services. Inventory planning is the process of determining optimal stock levels to meet that demand while minimizing costs. The accuracy of forecasting directly impacts the effectiveness of inventory planning.

Qualitative methods

These methods rely on expert judgment and market insights, and are especially useful for new products with limited or no historical data.

- Delphi method: Gathers forecasts from a panel of experts through multiple rounds of anonymous surveys. The process continues until a consensus forecast is reached.

- Market research: Collects information through customer surveys, interviews, and focus groups to gauge consumer preferences and intent.

- Sales force composite: Aggregates the demand forecasts from a company's sales and marketing teams, who often have direct market insights.

Quantitative methods

These techniques use historical data and statistical models to predict future demand and work best for products with established demand patterns.

- Time series analysis: Analyzes historical data to identify trends, seasonal patterns, and cycles to project them into the future.

- Moving averages: A simple method that averages past demand data over a specific period to smooth out short-term fluctuations and identify underlying trends.

- Exponential smoothing: A more advanced moving average technique that gives greater weight to recent data, making it more responsive to shifts in demand.

- Regression analysis: Examines the relationship between demand and other factors (e.g., price, promotions, or economic indicators) to build more comprehensive predictive models.

- Machine learning and AI: Uses powerful algorithms and large datasets to identify complex patterns that humans might miss, enabling highly accurate forecasts, especially in volatile markets.