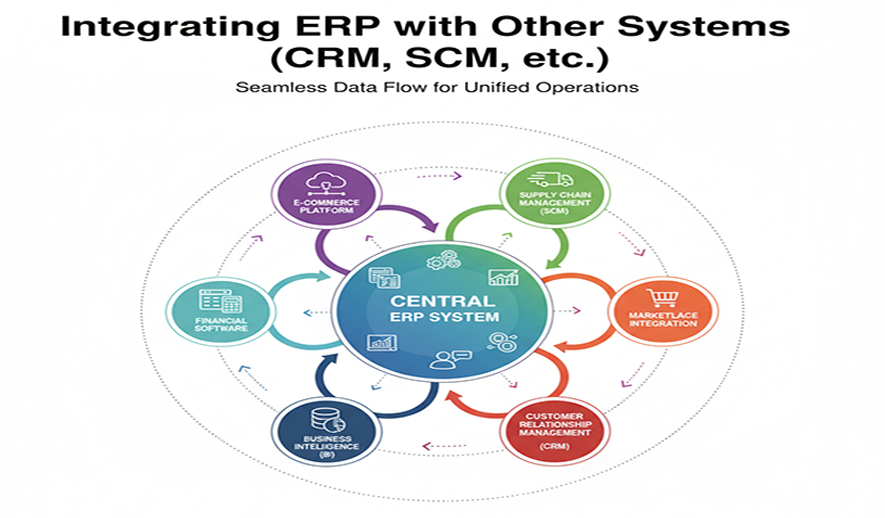

Integrating ERP with Other Systems (CRM, SCM, etc.)

The goal of integrating an Enterprise Resource Planning (ERP) system with other applications like Customer Relationship Management (CRM) and Supply Chain Management (SCM) is to break down data silos, automate workflows, and create a single source of truth across the organization. This allows different departments to access real-time, accurate, and consistent data, leading to improved efficiency, better decision-making, and a more streamlined customer experience.

Integrating ERP with Customer Relationship Management (CRM)

Integrating ERP and CRM systems connects front-office (customer-facing) activities with back-office (operational) processes.

Common use cases and benefits:

- 360-degree customer view: Sales and customer service teams get instant access to critical data from the ERP, such as order history, inventory levels, billing information, and payment status, allowing them to provide more personalized and efficient service.

- Accelerated sales process: Once a sale is closed in the CRM, the integration can automatically create a sales order in the ERP. This automates the quote-to-cash process, eliminating manual data entry and speeding up order fulfillment.

- Improved forecasting: By syncing sales forecasts from the CRM to the ERP, operations can better manage inventory and resources, helping to align demand with supply.

- Better resource allocation: Integrating customer data allows organizations to identify customer buying patterns and needs, which helps in better planning and resource allocation.

Potential challenges with CRM integration:

- Data incompatibility: ERP and CRM systems often have different data structures, which can complicate mapping customer and product information.

- Legacy systems: Older ERPs may lack the necessary APIs for seamless connectivity with modern CRM applications, requiring custom coding or middleware.

Integrating ERP with Supply Chain Management (SCM)

Integrating an ERP system with SCM applications provides a more comprehensive view of the supply chain, from procurement to production and delivery.

Common use cases and benefits:

- Real-time visibility: A centralized platform gives managers real-time insight into the entire supply chain, including inventory levels, purchase orders, production schedules, and logistics. This helps identify and resolve issues proactively.

- Optimized inventory: ERP integration automates inventory tracking and triggers reorders based on real-time data and demand forecasts, preventing stockouts and overstocking.

- Enhanced collaboration: Suppliers can be given access to shared portals to view order statuses and delivery schedules, improving communication and vendor relationships.

- Automated workflows: Processes like purchase order generation, invoice matching, and order fulfillment are automated, reducing manual effort and errors.