Common Challenges in ERP Implementation & How to Avoid Them

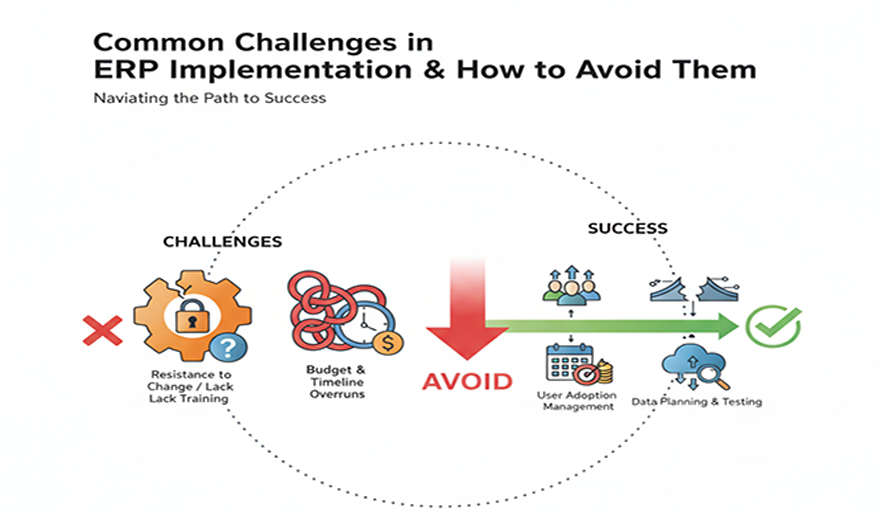

Implementing an Enterprise Resource Planning (ERP) system is a significant undertaking that affects nearly every aspect of an organization. While the benefits can be substantial, including increased efficiency and better data visibility, the process is also fraught with potential challenges. Understanding these common pitfalls and planning proactively can significantly increase your chances of a successful implementation.

Common ERP implementation challenges and solutions

1. Resistance to change

Employees may be comfortable with existing processes and wary of learning a new system, which can lead to low user adoption.

- How to avoid it: Involve employees early by creating a cross-functional project team with representatives from all departments. Communicate transparently and consistently about the project's purpose and how the new ERP will benefit them, not just the company. Provide extensive, role-specific training and ongoing support to build confidence.

2. Inadequate planning and unclear goals

Failing to establish a clear strategy from the start can lead to scope creep, budget overruns, and missed deadlines.

- How to avoid it: Define clear, measurable goals and key performance indicators (KPIs) before starting. Conduct a thorough business process review to understand your needs and create a detailed roadmap with realistic timelines and milestones.

3. Poor data quality and migration

Migrating inaccurate, duplicate, or incomplete data from old systems can carry over inefficiencies and corrupt the new ERP.

- How to avoid it: Prioritize data cleansing, validation, and standardization before migration begins. Use automated tools and perform test migrations to identify and fix issues early. Assign clear responsibilities to data owners within each department.

4. Unrealistic budgets and timelines

ERP projects often exceed their initial budget and schedule due to poor planning, unexpected costs, or scope creep.

- How to avoid it: Establish a realistic budget that accounts for hardware, software, implementation, training, and ongoing support. Include a contingency fund of 10–25% for unforeseen expenses. A phased implementation approach can also help manage costs and timelines by tackling the project in smaller, more manageable stages.

5. Customization overload

Over-customizing the ERP system to replicate existing processes can increase costs, complicate upgrades, and make the system harder to maintain.

- How to avoid it: Stick to the standard configurations and features of the new ERP as much as possible. Focus on adopting industry best practices that come with the software rather than forcing the new system to mimic old, inefficient workflows. Customize only when absolutely necessary for unique business needs.