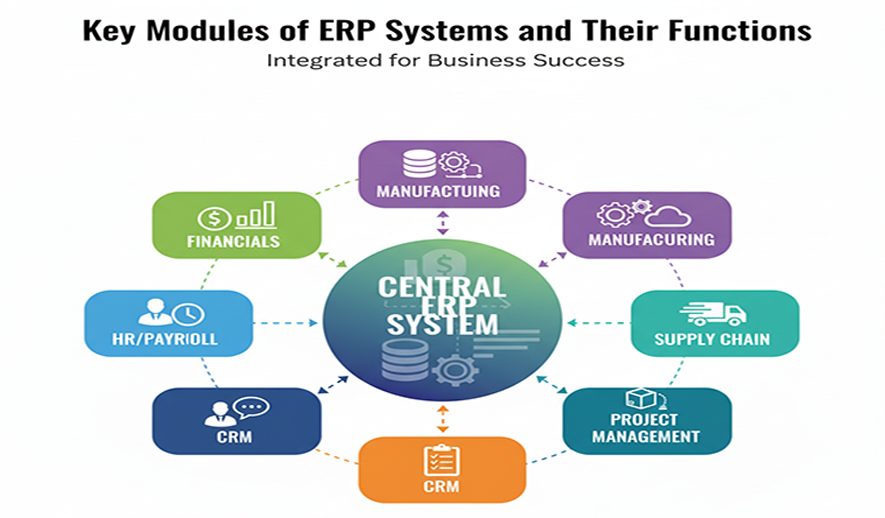

Key Modules of ERP Systems and Their Functions

Enterprise Resource Planning (ERP) systems consist of multiple integrated modules that work together to streamline core business processes. While the specific modules can vary by vendor and industry, most ERPs are built on a core set of modules, each with distinct functions.

Core ERP modules and their functions

Financial management

The financial management module is the foundation of any ERP system, providing a centralized platform for all accounting and financial data.

- General Ledger (GL): Records all financial transactions to provide a complete view of the company's financial health.

- Accounts Payable (AP): Manages all money owed to suppliers and other creditors.

- Accounts Receivable (AR): Tracks all money owed to the company by its customers and automates the invoicing process.

- Asset Management: Manages the life cycle of assets, including depreciation and maintenance.

- Financial Planning and Analysis (FP&A): Provides tools for budgeting, forecasting, and reporting to support strategic financial decisions.

Human resources (HR) management

This module, also known as Human Capital Management (HCM), stores and manages all employee-related data and automates HR processes.

- Payroll: Automates salary calculations, tax deductions, and benefits administration to ensure accurate and timely payments.

- Time and Attendance: Tracks employee work hours, leave requests, and overtime.

- Recruitment and Onboarding: Manages the hiring process, including job postings, applicant tracking, and onboarding new employees.

- Performance Management: Facilitates performance reviews, goal setting, and feedback collection.

Supply chain management (SCM)

The SCM module oversees and optimizes the entire flow of goods, from sourcing raw materials to delivering the finished product to the customer.

- Demand Planning: Forecasts customer demand to inform production and inventory levels.

- Procurement: Streamlines the purchase of goods and materials and manages vendor relationships.

- Inventory Management: Tracks inventory levels in real-time to avoid stockouts and minimize costs.

- Warehouse Management: Optimizes daily warehouse operations, including receiving, putaway, picking, and shipping.

Manufacturing

Designed for manufacturers, this module plans and manages the entire production process to improve efficiency and reduce waste.

- Production Planning: Coordinates production schedules based on demand forecasts and available capacity.

- Bill of Materials (BOM): Creates a comprehensive list of all raw materials, sub-assemblies, and components required to produce a finished product.

- Shop Floor Control: Provides real-time visibility into the production floor, monitoring work-in-progress and machine status.

- Quality Control (QC): Enforces quality standards throughout the production process to minimize defects.